INNOVATION

Cement’s Carbon Reckoning: Can Capture Deliver?

A major Alberta project could prove carbon capture’s role in cutting cement’s toughest emissions

9 Jan 2026

Carbon capture is shedding its reputation as a lab-bound idea in the cement industry. What once looked like an expensive gamble is starting to feel like a practical tool for cutting emissions from one of the world’s most carbon-heavy materials.

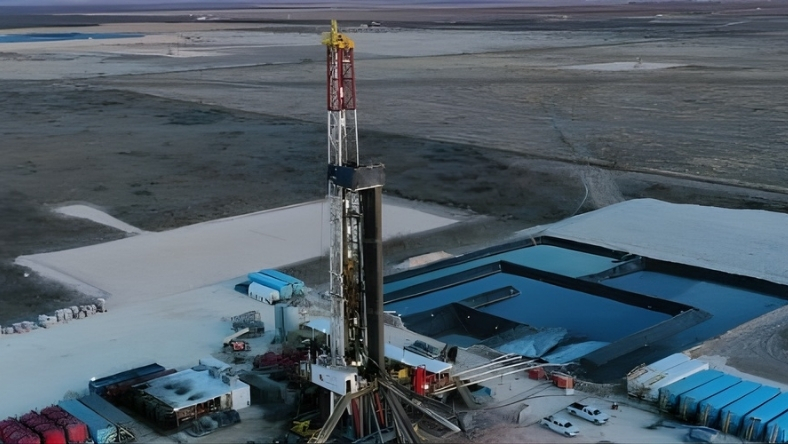

A major project near Edmonton is helping drive that shift. Lehigh Cement, backed by Heidelberg Materials and public funding, is building a carbon capture system designed to work alongside a fully operating cement plant. If completed as planned, it could capture between about 780,000 and 1,000,000 metric tons of carbon dioxide each year, with operations expected to begin in late 2026.

The project matters because cement has a problem that cleaner fuels alone cannot solve. Much of its pollution comes from the chemical process inside the kiln, not just from burning energy. Even the most efficient plants still release carbon when limestone is turned into clinker. Carbon capture tackles that reaction directly by trapping carbon dioxide before it escapes and storing it underground.

Scale is what sets the Edmonton project apart. This is not a small pilot bolted onto the side of a plant. It is designed to run continuously, in sync with daily production. For an industry with tight margins and little tolerance for downtime, proving that capture systems can operate reliably is as important as the emissions cuts themselves.

Government support has played a decisive role. High upfront costs have long slowed adoption, but shared risk and clearer rules around storage are helping projects move forward. That support also comes as demand for cement stays strong, fueled by infrastructure spending and growing pressure from buyers to lower the carbon footprint of building materials.

None of this comes without tradeoffs. Carbon capture adds cost, complexity, and energy use. It also raises long-term questions about who is responsible for stored emissions decades from now. And it does not remove the need to keep improving efficiency or explore new materials.

Still, for many cement makers, carbon capture is becoming hard to ignore. The Edmonton project is now a proving ground. If it works as planned, it could mark the moment when deep decarbonization in cement starts to look achievable at scale.

Latest News

17 Feb 2026

Montney Momentum: Ovintiv Doubles Down12 Feb 2026

Canada’s Carbon Strategy Fuels Next-Phase CCUS Growth11 Feb 2026

Atlantic Canada Eyes a Future Beneath the Seafloor9 Feb 2026

Canada Bets on Carbon Data to Unlock New CCUS Regions

Related News

PARTNERSHIPS

17 Feb 2026

Montney Momentum: Ovintiv Doubles Down

REGULATORY

12 Feb 2026

Canada’s Carbon Strategy Fuels Next-Phase CCUS Growth

INNOVATION

11 Feb 2026

Atlantic Canada Eyes a Future Beneath the Seafloor

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.